Nexen Tire Tech Center Grand Opening

Nexen Tire America celebrated the grand opening of its Tech Center in Richfield, Ohio, on Wednesday, capping off a banner year for the South Korean tiremaker.

The company opened its Nexen University R&D center in Seoul in April, its manufacturing facility in the Czech Republic in August, cut the ribbon on another tech center in Germany in September, and finally commemorated the opening of its state-of-the-art North American Tech Center on Wednesday.

“Here begins another exciting journey,” said Travis Kang, global CEO of Nexen Tire Corp, addressing the crowd of Nexen employees, local dignitaries, and company partners at the grand opening ceremony. “This new tech center is evidence of our commitment to the U.S. market. Here we will develop the tires to help Nexen achieve its goal of becoming a top-tier tiremaker by 2025.”

Scroll down to look at highlights from the opening ceremony and tour the high-tech center.

Aaron Neumann, product development manager for Nexen Tire’s North American Tech Center, addresses the crowd describing how Nexen’s Tech Center will be the “outpost for R&D” to develop tires for the “unique demand and performance requirements” for the North American market.

Bobbie Beshara, mayor of the Village of Richfield, tells the crowd, “We are more honored than you can imagine that you are part of our community,” at the grand opening ceremony for Nexen Tire’s North American Tech Center.

Nexen Global CEO Travis Kang shares how Nexen’s North American Tech Center fits into the company’s plan for North American growth.

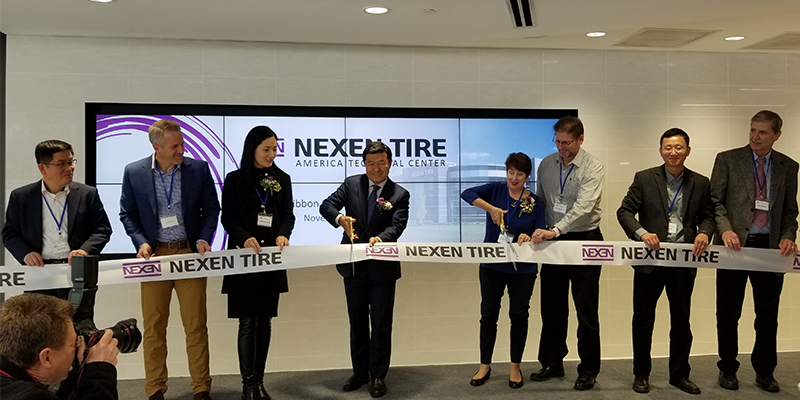

Nexen officials, as well as local dignitaries and the company’s partners, cut the ribbon signifying the grand opening of Nexen’s Tech Center. (left to right) President of Nexen Tire America Jong Sun Kim; Fiat Chrysler Automobiles Head of Brakes, Wheels, and Tires Purchasing Joe Welch; Wonsun Jung, wife of Nexen Global CEO Travis Kang; Travis Kang; Village of Richfield Mayor Bobbie Beshara; Dan Wysocki, Fiat Chrysler automobiles systems & component chassis engineering, design responsible manager for tires, Don Lee, head of Nexen Tire America Technology Center and retired Nexen Project Engineer Gary Zolton.

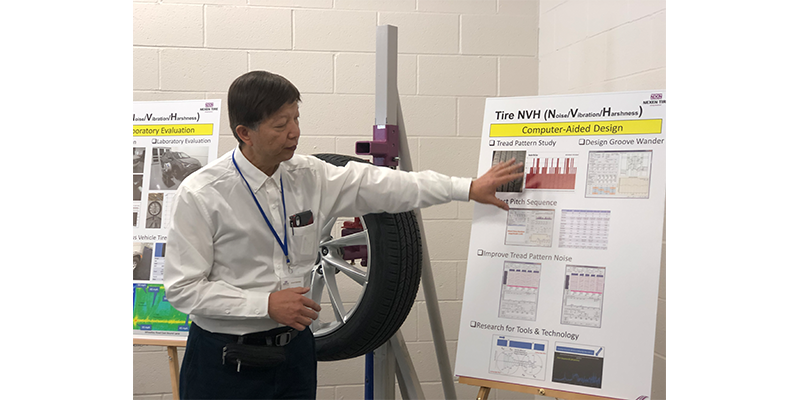

Lin Kung, project manager for Nexen Tire’s North American Tech Center, explains to the crowd how Nexen conducts its NVH (noise, vibration, and harshness) testing.

During the tour, Nexen described how it works with enthusiasts to test its tires in conditions across the U.S. Here, a local enthusiast’s vehicle, a 2001 Honda S2000 modified with a Corvette LS3 engine, TKO 600 five-speed manual transmission, Ford 8.8 differential, GT500 brake rotors with Corvette C6 calipers and TSW 18-in. wheels come equipped with Nexen N’ SUR4G with 225/40R18 88Y in the front and 275/35R18 95Y in the rear.

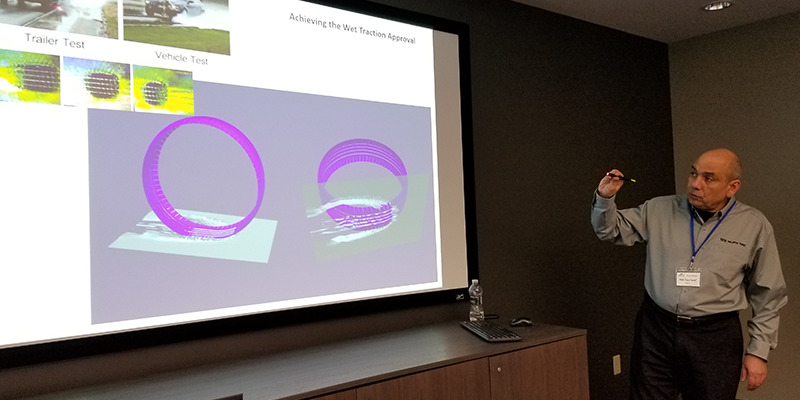

Dean Rogers, section manager for tire technology, explains how Nexen’s tires are made using 3-D computer modeling.

Jan Terziyski, program manager at Nexen Tire’s North American Tech Center, explains how Nexen’s tires are tested in the elements.

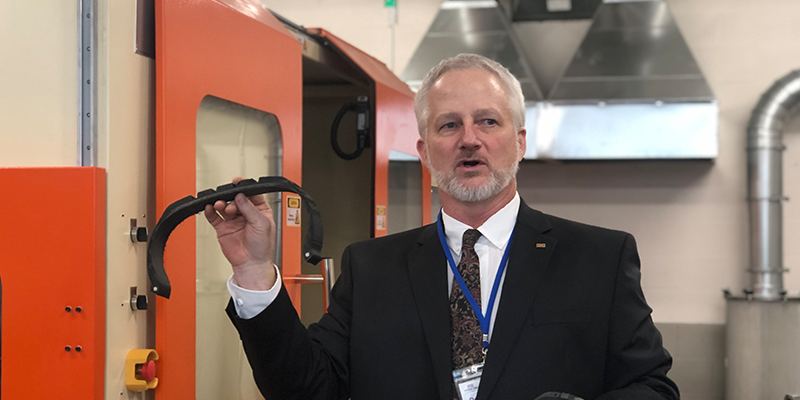

Dean Rogers, section manager for tire technology, shows off the finished product from Nexen’s wire-cutting tire section machine.

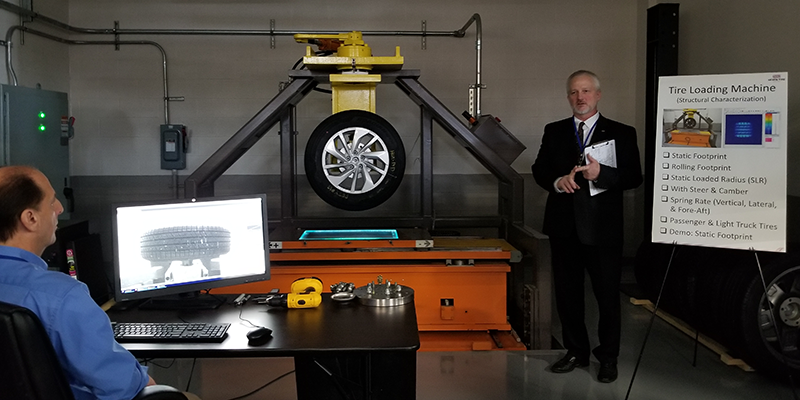

Dean Rogers, section manager for tire technology, explains how Nexen tests different structural characteristics of the tires it creates.

Construction on Nexen Tire America’s 33,540 square-foot Tech Center in Richfield, Ohio was finished late last year.