NEXEN TIRE Shifts Paradigm in Tire Development Process with XAI and 3D Printing Technology

– XAI proposes optimal designs that meet the performance and requirements

– Patented 3D printing technology significantly reduces development time

SEOUL, South KOREA, August 21, 2024 – NEXEN TIRE, a leading global tire manufacturer, is transforming the tire development paradigm by integrating advanced technologies, including XAI (eXplainable AI)-based design processes and 3D printing for mold production. NEXEN TIRE, which has proven its quality and technology by supplying OE tires for premium automakers, aims to further expand its partnerships with global automakers through these innovations.

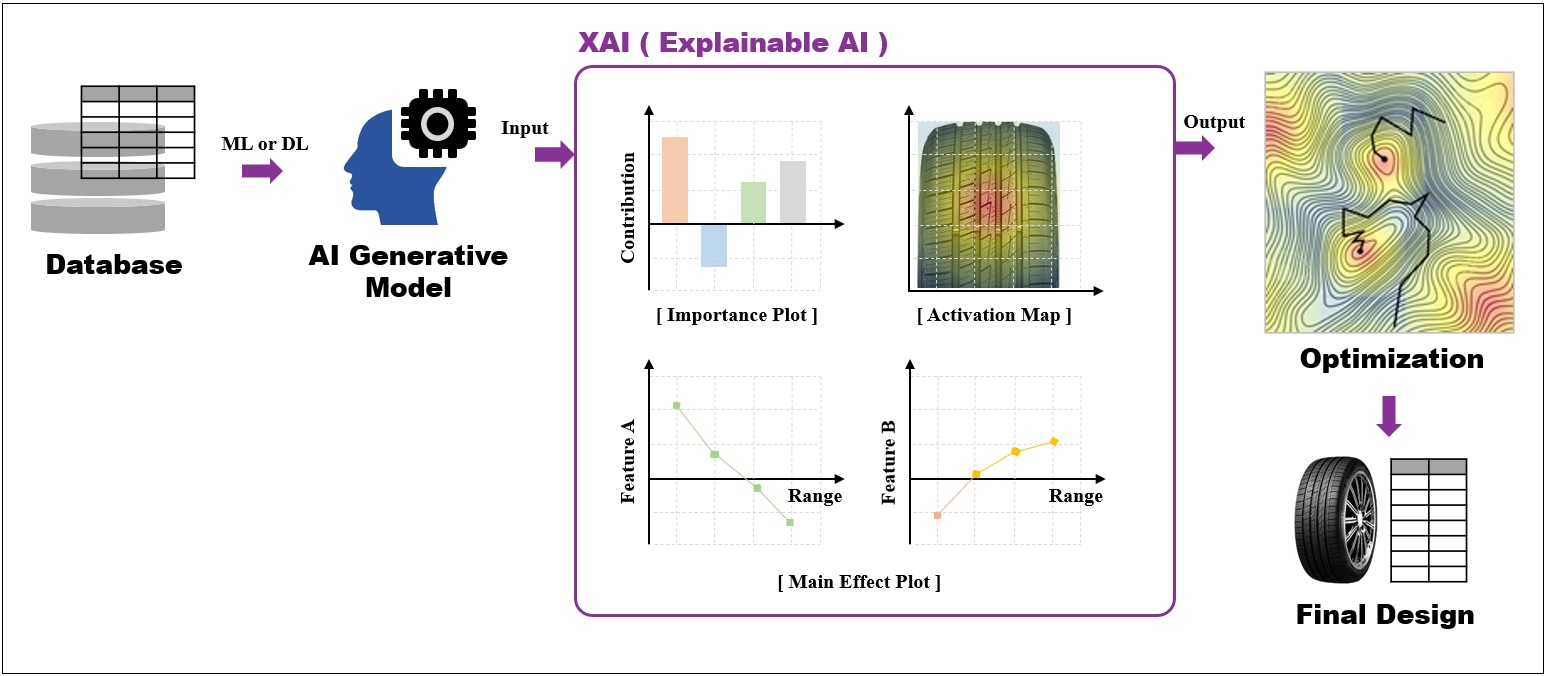

The traditional tire development process involves designing structures and patterns, creating molds, manufacturing prototypes, and finally testing them on vehicles to achieve final product approval. NEXEN TIRE has successfully streamlined this process and enhanced product precision by incorporating XAI and 3D printing technologies into tire development.

XAI is an artificial intelligence technology that helps understand and analyze the causes and processes behind the results generated by machine learning algorithms. By analyzing various information such as basic designs, key design variables, performance contributions, and design directions, it maximizes tire design efficiency and proposes the optimal structure and design that meets the requirements of tire developers.

NEXEN TIRE leverages XAI-driven designs to create Virtual Tire Models, assessing product performance in virtual environments, thereby increasing accuracy and speed in tire development. The recent decision to adopt a driving simulator, a first in the domestic industry, is expected to elevate virtual development to a new level.

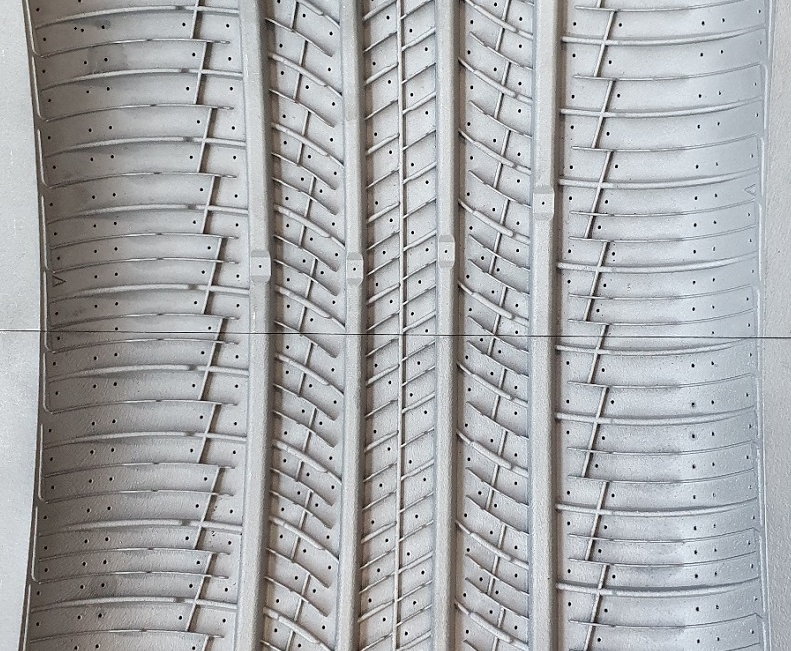

Once a model passes the virtual development stage, a physical prototype is produced for final evaluation, which requires the production of a mold—the framework used to shape the tire. NEXEN TIRE utilizes 3D printing technology to produce molds, enabling the simultaneous creation of prototypes in various designs and specifications. As these prototypes have already undergone a stage of verification in the virtual development process, the chances of final product approval are significantly increased.

Traditionally, mold production alone took two to three months, but with 3D printing, this period can be cut by at least 70%. Additionally, production costs can be reduced by at least 50%, ensuring cost efficiency from the early stages of development.

The 3D printing-based mold manufacturing technology allows for innovative tire designs that include diverse and complex patterns as well as(tiny slits on the tread). This is crucial for supporting high-performance vehicles and provides consumers with enhanced performance and safety. NEXEN TIRE applied for an international patent for its 3D printing technology, which incorporates proprietary ideas.

By innovating its development process, NEXEN TIRE is enhancing product competitiveness while reducing time and costs. The company is also contributing to sustainable management by reducing the amount of waste and costs associated with discarded prototypes, supporting environmentally friendly development practices.

“The ultimate goal of our technological innovations is to enhance customer satisfaction.” A NEXEN TIRE representative stated, “Transforming the tire development process not only secures market competitiveness but also contributes to environmental protection during the development process, shaping the future of tire manufacturing and driving revolutionary change.”